Digital Photopolymer Plates

Flexographic printing plates play a crucial role in the flexo printing process, serving as the medium for transferring ink onto various substrates. Advancements in plate-making technologies have enhanced the quality and capabilities of flexo printing, making it a preferred choice in the packaging and label printing industries.

Precision Imaged Durable Plates

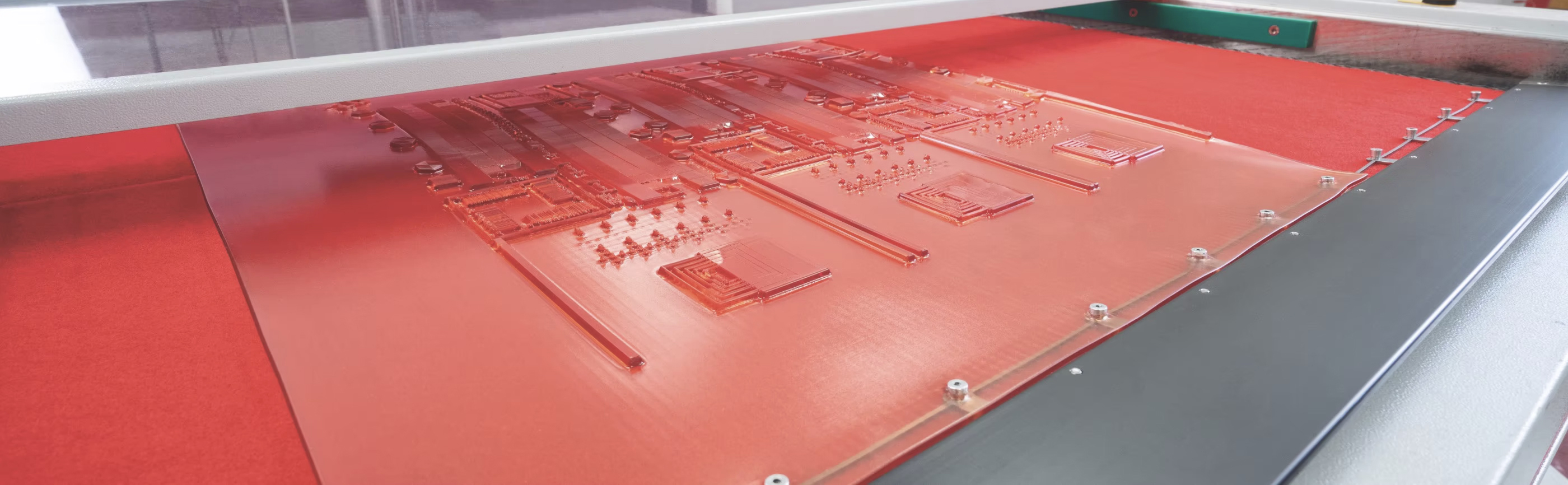

Material: Flexo plates are usually made of flexible photopolymer materials. These materials are sensitive to UV light and are commonly used due to their ability to hold fine details and withstand the stresses of the printing process.

Plate Making Process: The creation of flexo plates involves a plate-making process called photopolymerization. A photosensitive polymer material is exposed to UV light through a film negative containing the desired image. The UV light hardens the polymer in the areas exposed, creating a relief image on the plate.

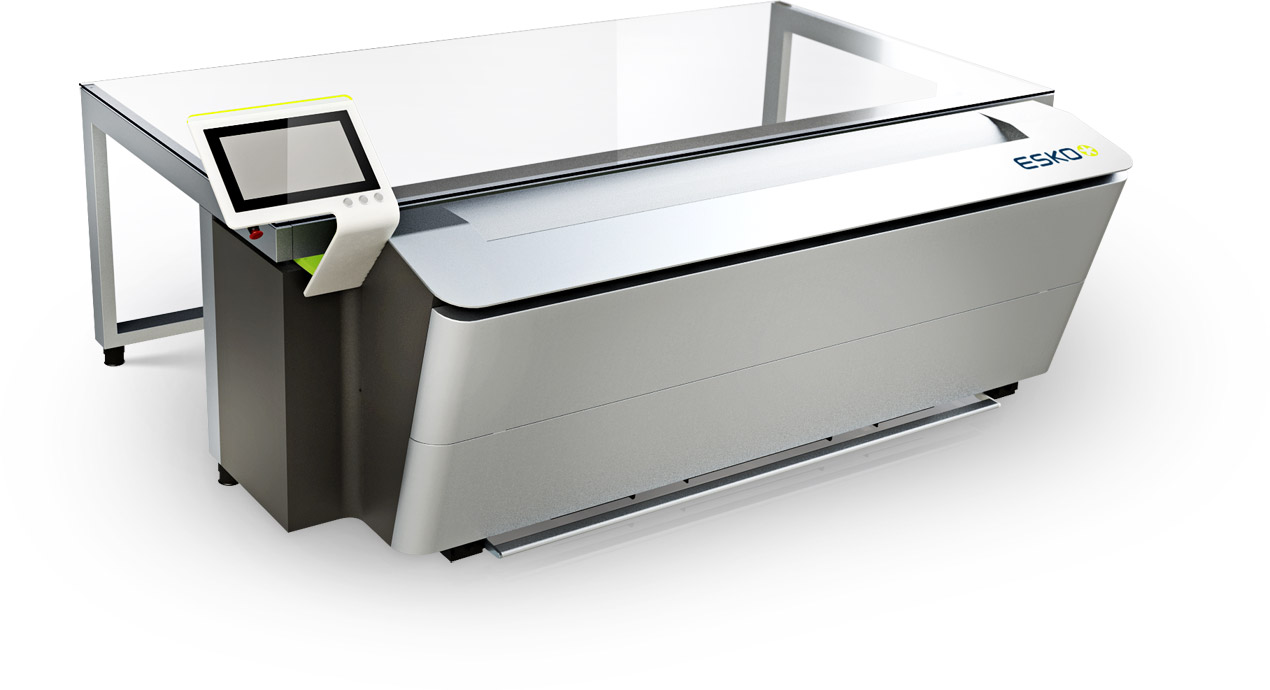

Plate Mounting: Flexo plates are mounted onto cylinders on the printing press. These cylinders transfer ink to the printing substrate (such as paper, film, or labels) as it passes through the press.

Printing Process: During the printing process, the flexo plate's raised surface areas receive ink. This ink is then transferred directly onto the substrate material, creating the desired image or text.

Digital Flat Top Dot Plates

Applications: Flexographic printing is commonly used for various packaging materials, labels, newspapers, corrugated boxes, flexible packaging, and more. It is suitable for both long and short print runs.

Advantages: Flexo printing offers advantages such as high-speed printing capabilities, versatility in printing on different substrates, the ability to use a wide range of inks (water-based, solvent-based, UV-curable), and relatively low production costs.

Limitations: While flexo printing is versatile, achieving very high-resolution images and fine details may be more challenging compared to some other printing methods like offset or digital printing.